Bolted tanks have been a popular storage solution in the oil industry for decades. These steel storage tanks are made up of individual panels that are bolted together on-site, creating a large, durable, and flexible storage solution that can be customized to fit specific requirements. In this blog, we will explore the relevance of bolted tanks in the oil industry and their many advantages.

Key Advantages of Bolted Tanks in the Oil Industry

- Flexibility – Bolted tanks can be customized to fit specific requirements, whether it’s for oil storage or for water treatment. They can be constructed in various sizes and shapes, and the number of panels can be adjusted as per the needs. This flexibility is critical when dealing with limited space or unusual site conditions.

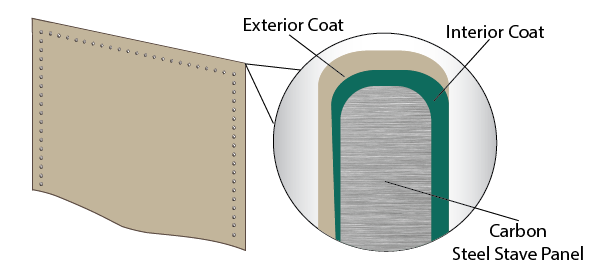

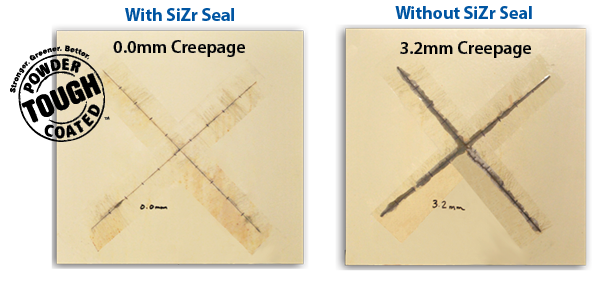

- Durability – Bolted steel storage tanks are designed to withstand harsh weather conditions and corrosive substances, such as oil. They are made of high-quality steel, which is coated with a protective layer to prevent rust and corrosion. This makes them a reliable and long-lasting storage solution for the oil industry.

- Cost-Effective – Bolted tanks are an affordable alternative to other storage solutions, such as welded steel tanks or concrete tanks. They require less maintenance, which makes them a cost-effective storage solution in the long run.

- Easy Installation – Bolted tanks can be installed quickly and easily. The individual panels can be transported easily to the site and assembled on-site, which reduces transportation and labor costs. This quick installation time is especially important in the oil industry, where time is of the essence.

- Easy Maintenance – Bolted steel tanks require minimal maintenance. The protective coating on the steel panels prevents corrosion and rust, and any damaged panels can be easily replaced without having to dismantle the entire tank.

- API Spec Q1 – Superior Tank Co., Inc. is one of two storage tank manufacturers in the world certified with the prestigious API 12-B Monogram and the API Spec Q1 license. The API Monogram licensing program ensures that all products manufactured by Superior Tank are in conformance to product specifications and management system requirements.

The oil sector requires a reliable and durable storage solution that can withstand the harsh conditions of oil storage. Bolted tanks offer the flexibility and durability that the industry needs. They can be customized to fit specific requirements, and their cost-effectiveness makes them an attractive storage solution for the industry.

Bolted storage tanks are used in the oil industry to store crude oil, refined products, and other substances such as water, brine, and chemicals. They are also used for water treatment, which is a critical process in the oil industry. Bolted tanks are used to store water for injection into oil wells, which helps to increase oil production.