As bolted steel and welded steel tanks have evolved over the last 50 years, so has the technology and machinery used to manufacture the tanks. Superior Tank currently uses numerous advanced pieces of equipment including A.R.T. (Automated Robotic Technology). A.R.T. is used in the Rancho Cucamonga manufacturing facility to precisely weld raw materials together to form various tank components.

A.R.T. is a 300lb robot featuring 6 axis of articulation allowing A.R.T. to accurately weld joints in even hard to reach areas. All aspects of the welding process including power, wire, speed and angle of approach are regulated by the computer for extreme consistency and 100% accurate welds. In addition to the accuracy and strength of the welds, the seams are also smoother allowing for better coating coverage and corrosion protection. As errors and weak areas are eliminated, fewer parts are rejected and material waste is minimized.

A.R.T. is used for a variety of tank parts and accessories used with steel water and oil tanks. For example, tank nozzles, flanges, manways and piping are welded together in the factory. When these components are used with bolted tanks, the parts are powder coated then shipped with the tank kit to the installation site. For welded steel tank use, the parts are field coated after being installed onsite.

A.R.T. and other technologically advanced equipment allows Superior Tank to custom fabricate numerous steel tank elements with unmatched precision.

When purchasing a Bolted Steel Tank from Superior Tank, customers have several choices of gaskets. We offer three different premium gasket materials for our steel storage tanks: EPDM, Viton or Buna-N. Selecting the proper gasket material can make a significant difference in the lifespan of the tank.

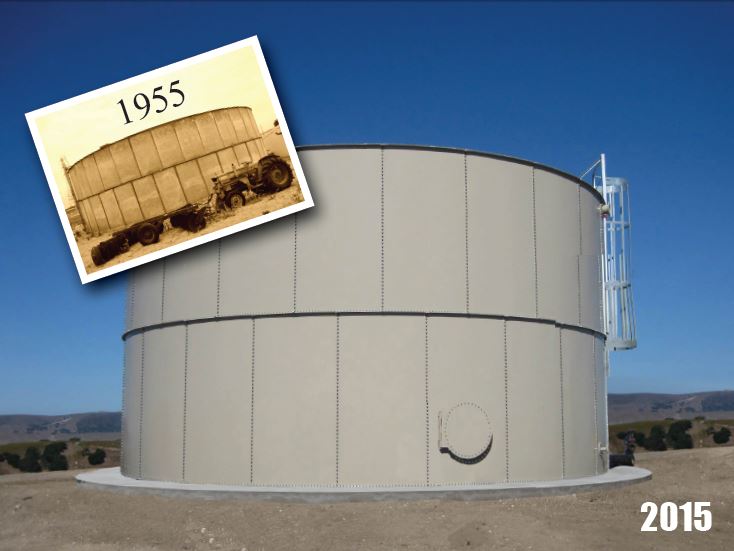

When purchasing a Bolted Steel Tank from Superior Tank, customers have several choices of gaskets. We offer three different premium gasket materials for our steel storage tanks: EPDM, Viton or Buna-N. Selecting the proper gasket material can make a significant difference in the lifespan of the tank. Superior Tank Co., Inc. (STCI) recently completed the manufacturing and installation of a water storage tank for fire protection. The bolted steel water storage tank has a capacity of 320,000 gallons and was installed at the remote testing facility of a large international company.

Superior Tank Co., Inc. (STCI) recently completed the manufacturing and installation of a water storage tank for fire protection. The bolted steel water storage tank has a capacity of 320,000 gallons and was installed at the remote testing facility of a large international company.

Since 1988, the United States has experienced a significant decline in the number of welders. According to the American Welding Society there is a potential shortage of 200,000 skilled welders resulting in project delays and increased costs.

Since 1988, the United States has experienced a significant decline in the number of welders. According to the American Welding Society there is a potential shortage of 200,000 skilled welders resulting in project delays and increased costs.

Of all the questions we are asked while attending trade shows all over the world, the following questions are the two most common: first; “What are the advantages of factory powder coated tanks over glass-coated tanks?” and “are they really cheaper than glass-coated tanks?”.

Of all the questions we are asked while attending trade shows all over the world, the following questions are the two most common: first; “What are the advantages of factory powder coated tanks over glass-coated tanks?” and “are they really cheaper than glass-coated tanks?”.