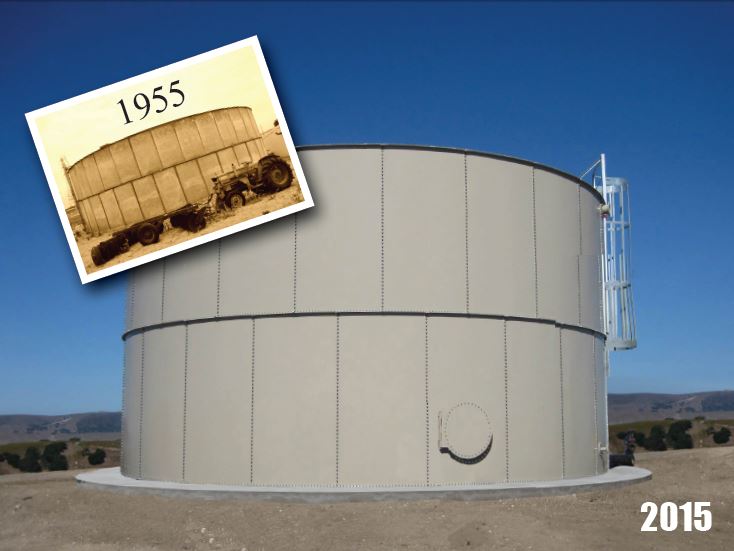

Bolted steel tanks have been used for storage for many years and some older tanks are in use today. Since the first bolted tanks were put into service decades ago there have been numerous advances in their design and construction.

Modern bolted steel tanks are designed differently than from tanks 30 years ago. Bolted steel tanks are now designed using 3D modeling software, increasing the speed and accuracy of the process. Select projects are designed using simplified Building Information Model (BIM) software which encompasses the entire project from design to manufacturing then installation. The BIM system can store beneficial ancillary information such as weight and dimension of components and materials used to build the tank. Design standards such as the AWWA D103 have improved over the last several decades resulting in longer lasting and better performing tanks. In addition, new tanks are more structurally sound thanks to advances in seismic and wind design methods.

In addition to tank design, the manner in which bolted steel tanks are manufactured has progressed. Originally, steel tanks were manufactured by fabricating raw material by hand or with basic equipment. Small variations in the individual components led to leaks as parts did not fit together properly. Today, bolted steel tanks are precision fabricated using specialized machinery in State of the Art factories. CNC automated machinery ensures extreme accuracy and reduces the fabrication time. Tank accessories are joined together using robotic welding equipment for 100% perfect joints. In addition, by earning ISO 9001:2008 Certification and following strict procedures, manufacturers can guarantee product consistency and quality.

Innovative options such as factory powder coating have significantly increased the longevity of bolted steel tanks. The powder coating application process includes spraying a SiZr liquid seal to the prepared steel. The powder coating is applied dry to the steel in an environmentally controlled area to eliminate surface imperfections. The coating is electrostatically applied for 100% coverage without runs, drips and voids. Powder coating formulas are now specially designed for the application; epoxy coating on the interior for continuous emersion and TGIC Polyester on the exterior for outstanding resistance to UV exposure. Once the powder coating is thermoset using mild temperature ovens, it chemically reacts with the steel to form a permanent bond. As all steel components including inaccessible areas such as the underside of the tank bottom are sealed with powder coating the entire tank structure is protected against corrosion.

The hardware used with modern bolted steel tanks has also improved since bolted tanks were first used. To ensure maximum durability of bolted steel tanks, new nut and bolt options were introduced. Encapsulated nuts and bolts are best suited to specific uses and protect against hardware corrosion. In other applications, hot dipped galvanized nuts and bolts are the best alternative. In addition, the strength of the hardware has increased and bolts used today have a tensile strength of over 120,000 lbs per square inch and now Grade 5 and Grade 8 bolts are used in place of Grade 2. Such advances in tank design, manufacturing processes and materials allow bolted steel tanks up to 3,500,000 gallons to be built.

A final significant improvement which has improved the longevity of bolted steel tank is the introduction of heavy duty synthetic gasket material which is used in place of putty mastic. New gasket material such as ethylene propylene diene monomer (EPDM) is specifically formulated for storage of potable water, wastewater and even brine water. The thick gaskets are precisely fabricated to fit into the seam between the steel tank panels and provide decades of leak free service. The gaskets remain flexible and therefore they are able to prevent leaks even as the steel expands and contracts due to temperature fluctuations and seismic movement.

When all of these advances are considered, it is easy to see how modern bolted steel tanks are very different than your Father’s Bolted Steel Tank.