COVID-19 UPDATE

TO OUR VALUED CUSTOMERS / VENDORS

As our industry and products are considered essential business for the american infrastructure we will continue operations on regular business hours during the COVID-19 Health Emergency.

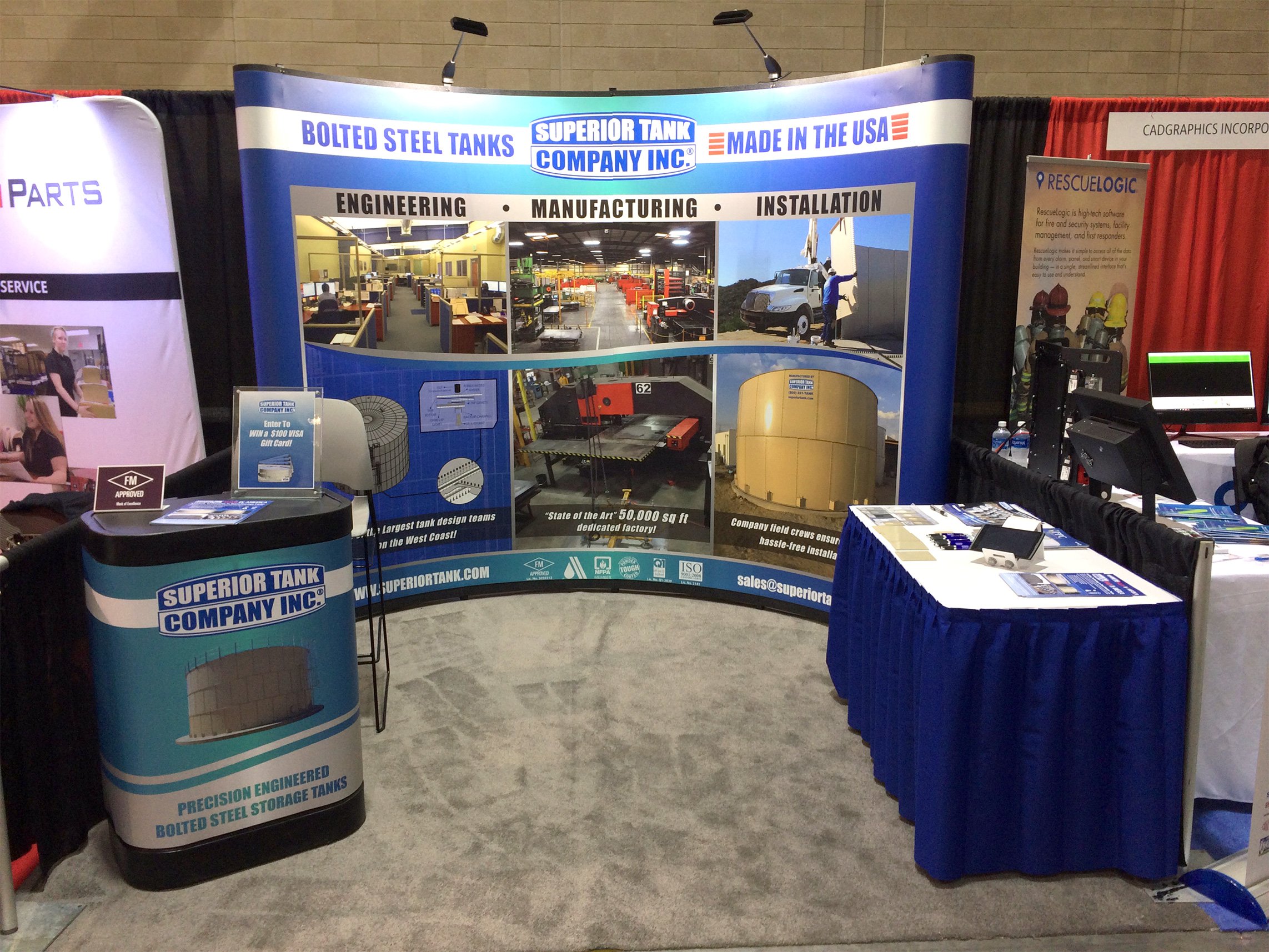

Click here for an update from Superior TankSUPERIOR BOLTED AND WELDED STEEL STORAGE TANKS

Superior Tank can help with everything for water and oil storage; from tank engineering, bolted & welded tank manufacturing and tank installation. We were founded on three basic principles: continuous innovation, a focus on quality and treating people with respect and integrity.

SAFETY THROUGH LEADERSHIP

Superior Tank is dedicated to cultivating a strong safety presence throughout the company and implementing safety measures, especially throughout the installation process. With the support of management and all employees, we have been able to develop a safe and secure installation process resulting in a high-quality final product which meets our customers’ needs.

We proudly received the RAVS Plus participant designation from ISN, reflecting our commitment to effective and compliant EHS policies.

Only 11% of ISN subscribers have participated in this rigorous evaluation process.

SAFETY INSPECTIONS

Our internal safety teams perform over 2,200 safety inspections both at our manufacturing facilities and in the field per year. That’s nearly 2,000 hours!

SAFETY MEETINGS

Our manufacturing and installation teams hold over 1,600 meetings per year totaling over 500 hours.

SAFETY EXPERIENCE

Our Safety Managers have a combined 40 years of experience!

CERTIFICATIONS

We currently hold 22 nationally recognized certifications, ensuring that we hold our employee safety and tanks to the highest standard.

FOLLOW US @SUPERIOR_TANK